- D/618/7406 Unit 5: Challenges of IT Security in Modern Organizations – Risks, Solutions & Best Practices

- HSC Level 2/3 Unit 012 Assignment: Care Worker Responsibilities and Ways of Working

- CIPD Level 5HR03 Assignment: Understanding Reward Approaches and Their Impact on Performance and Contribution

- CIPD level 5HR02 Assignment: Talent Management and Workforce Planning Unit Guide

- Level 3 D/615/3823 Assignment: Regulation, Protection, and Collaborative Practice in Health and Social Care

- PGM216D Assignment: Bicycle Store Sales Management Application

- MATH6033 Assignment: Epidemiological Investigation of Cardiovascular Health and Tea Consumption Risks

- EH6147 Assingment: Stakeholder Analysis for Quality Improvement in Hand Hygiene Compliance

- Assignment: Investigation of Solution Concentration Through Standard Preparation, Titration, and Colorimetry Techniques

- MATH6033 Assignment: Cardiovascular Risk and Tea Drinking: Epidemiological Analyses

- CIPD level 3 3CO03 Assignment: Core behaviours for people professionals

- DAC4B1: Personal development in adult care settings

- Unit 19 Research Project Assignment 1: Impact of Corporate Social Responsibility on Business Success & Community Wellness

- EG5022 Assignment: Georeferencing and Accuracy Assessment of a Quarry 3D Model Using Photogrammetric GCPs

- Assignment: Financial Performance and Strategic Analysis of a UK Listed Company: A CORE Evaluation and Reflective Review

- 5CNMN002W Assignment: Advanced measurement- Major measurement taking off

- K/650/2298 Level 3 Understanding Roles, Responsibilities, and Effective Partnerships in Health and Social Care

- Understanding Information and Knowledge Management in the Workplace: A Briefing for HR Professionals

- HRM7010D Strategic Use of People Analytics in Enhancing Organisational Value and Agility

- TOWN1060 Urban Planning in the UK History Sustainable Design and Future City Development

A lab scale 2L bioreactor operates at a volumetric productivity of 4 g L-1 h1 and is integrated with a cylindrical 400 mL separator: Chemical Engineering, Assignment, UCL, UK

| University | University College London (UCL) |

| Subject | Chemical Engineering |

Questions

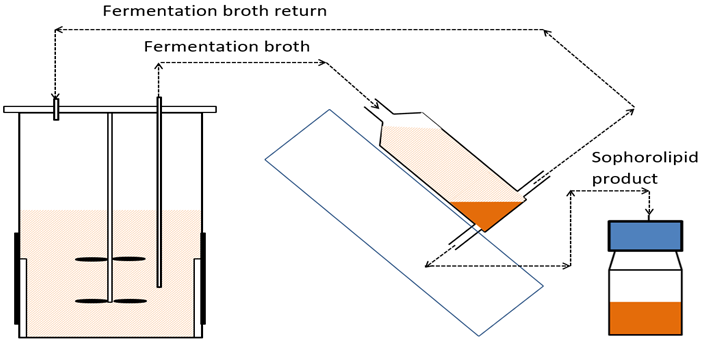

1. A lab scale 2L bioreactor operates at a volumetric productivity of 4 g L-1 h1 and is integrated with a cylindrical 400 mL separator (Figure 1) with an L/D ratio = 4. The residence time in the separator is 16 min. The system described is characterised by Re = 105. The fermentation broth is characterised by μa = 0.25 Pa.s, p = 1050 kg m23.

Do You Need Assignment of This Question

a) Calculate the current length and diameter of the separator in operation.

b) If residence time is reduced to 8min will there be an interference on settling?

2. Propose an approach for scaling up the lab scale separator described above for a bioreactor volume of 10 m3, operating at the same volumetric productivity and a maximum residence time of 16 min (see Figure 1).

- Discuss your considerations for the basis of performing the scale up design.

- State any relevant parameters for design and / or verification.

- Detail any further measurements which would be needed to support the scale up design.

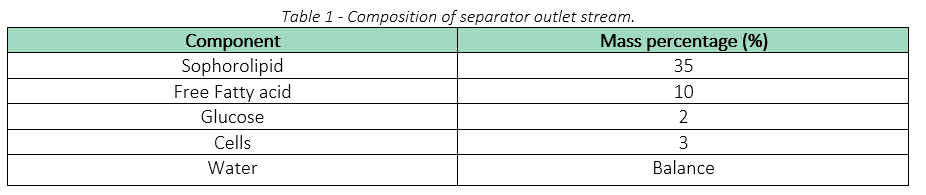

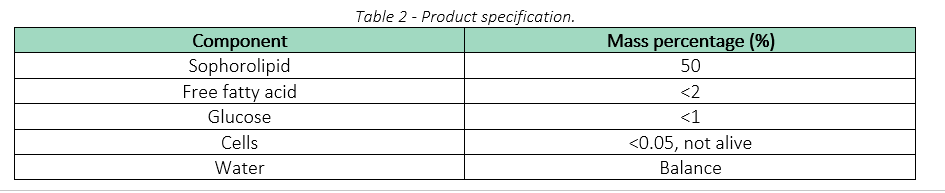

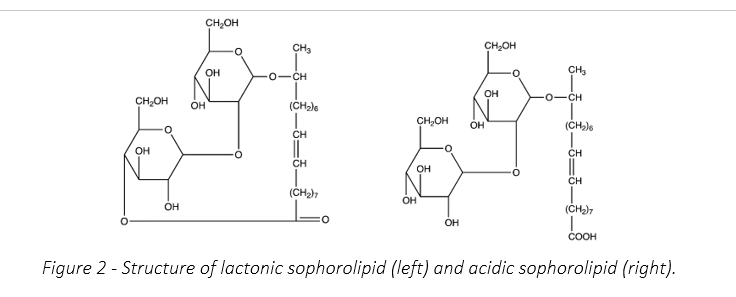

3. Propose a downstream procedure to ensure that the final product, taken from the separator and having the composition shown in Table 1, meets the specifications given in Table 2 so it is suitable to sale to customers. Aim to provide a process that can be applied industrially for as low a price as possible. State any assumptions and trade-offs/compromises in the design.

Buy Answer of This Assessment & Raise Your Grades

Are You Looking for Answer of This Assignment or Essay

Are you struggling with your Chemical Engineering assignment? Our Assignment Help Company in the UK is here to make things easier for you. If you need someone to do your assignment for you, or engineering assignment writing help online, we’ve got you covered. UK students can pay our expert to get the professional support they need to excel in their courses.