- D/618/7406 Unit 5: Challenges of IT Security in Modern Organizations – Risks, Solutions & Best Practices

- HSC Level 2/3 Unit 012 Assignment: Care Worker Responsibilities and Ways of Working

- CIPD Level 5HR03 Assignment: Understanding Reward Approaches and Their Impact on Performance and Contribution

- CIPD level 5HR02 Assignment: Talent Management and Workforce Planning Unit Guide

- Level 3 D/615/3823 Assignment: Regulation, Protection, and Collaborative Practice in Health and Social Care

- PGM216D Assignment: Bicycle Store Sales Management Application

- MATH6033 Assignment: Epidemiological Investigation of Cardiovascular Health and Tea Consumption Risks

- EH6147 Assingment: Stakeholder Analysis for Quality Improvement in Hand Hygiene Compliance

- Assignment: Investigation of Solution Concentration Through Standard Preparation, Titration, and Colorimetry Techniques

- MATH6033 Assignment: Cardiovascular Risk and Tea Drinking: Epidemiological Analyses

- CIPD level 3 3CO03 Assignment: Core behaviours for people professionals

- DAC4B1: Personal development in adult care settings

- Unit 19 Research Project Assignment 1: Impact of Corporate Social Responsibility on Business Success & Community Wellness

- EG5022 Assignment: Georeferencing and Accuracy Assessment of a Quarry 3D Model Using Photogrammetric GCPs

- Assignment: Financial Performance and Strategic Analysis of a UK Listed Company: A CORE Evaluation and Reflective Review

- 5CNMN002W Assignment: Advanced measurement- Major measurement taking off

- K/650/2298 Level 3 Understanding Roles, Responsibilities, and Effective Partnerships in Health and Social Care

- Understanding Information and Knowledge Management in the Workplace: A Briefing for HR Professionals

- HRM7010D Strategic Use of People Analytics in Enhancing Organisational Value and Agility

- TOWN1060 Urban Planning in the UK History Sustainable Design and Future City Development

Consider that you are part of a team responsible for debottlenecking the process shown in Fig.1 to make it more energy-efficient: Chemical Engineering Assignment, UOC, UK

| University | University Of Cambridge (UOC) |

| Subject | Chemical Engineering |

Description

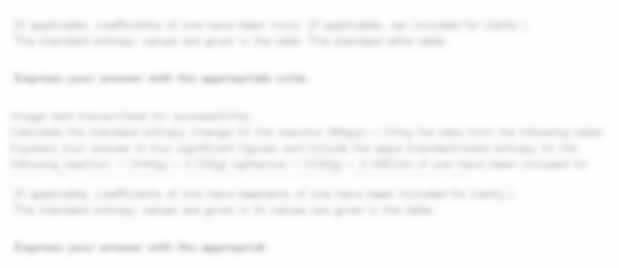

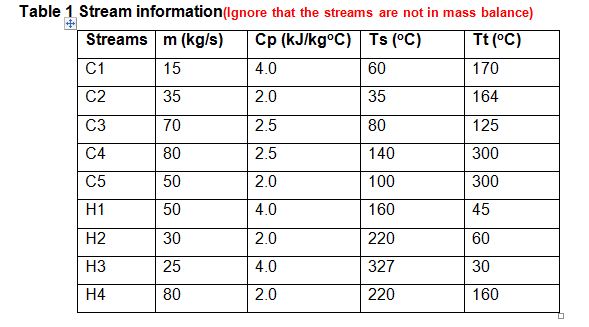

Consider that you are part of a team responsible for debottlenecking the process shown in Fig.1 to make it more energy-efficient. In the PFD, 9 streams have been highlighted (RED for hot streams and BLUE for cold streams. Hot streams are labeled H1 to H4 and cold streams are labeled C1 to C5 ). The information for the highlighted streams – mass flow rate, specific heat capacity, start and target temperature (i.e.: Ts and Tt) are given in Table 1. The minimum approach temperature for this process is 10oC.

Do You Need Assignment of This Question

- Provide an evaluation of the external utility cost (cooling water and steam) for the heat exchangers (HX1 to HX9) as shown in Fig 1

- Illustrate a strategy for reducing external utility use in the process. This should be shown using the HEN grid.

- Provide an evaluation of the external utility cost (cooling water and steam) for the modified process.

Buy Answer of This Assessment & Raise Your Grades

Students Assignment Help UK is the one-stop website for your all engineering assignments. our native writers are English speakers and they understand your project need and offer error-free assistance on essay writing, dissertation writing, online exam help, report writing, etc before the deadline.