- IF1201 Assignment: Developing Financial and Utility Tools Using VBA in Excel

- MA12009 Exploratory Data and Statistical Analysis of Airbnb and Spotify Datasets

- NVQ Level 5 Unit 507 Safeguarding in Adult Care

- Structural Design of a 4m Roof Beam: Load and Stability Analysis, Assessment 2

- M33118 Configuring and Studying ASA Basic Settings and Firewall Using CLI

- The Reasons For Hitler Gaining Power In 1933, Course Work

- Sensitivity Analysis of Option Pricing: Impact of Volatility and Barrier Conditions

- Network Threats and Vulnerabilities, UNIS, Coursework

- Corporate Finance and Business Valuation Coursework

- 5301ELE Digital System Evaluation Coursework, Level 5, LJMU 2024

- Power Electronic Applications and Control Coursework 1 2024

- PE7007 Construction Economics, Coursework Brief – 2024/2025 , NU, UK

- Level 3 Diploma in Adult Care, Coursework, UK: Understand the application of personcentred practices in care settings

- Decide whether each of the following statements is true or false. Justify your answer in each case by giving an example or stating any general result seen at the lecture: Mathematics, Coursework, NU, UK

- 7CO03: Critically assess different ethical standpoints on people practice and the maintenance of high standards of ethical behaviour: CIPD level 7 , Coursework, UK

- SQE2: Oral Skills-Written Skills- Apply the law comprehensively to the client’s situation, identifying any ethical and professional conduct issues: Reflective Portfolio, Coursework, UK

- SQE 1 Preparation: Portfolio Assessment-analyse and reflect upon your development of the practical legal skills that the Solicitors Regulation Authority (the SRA) : Reflective Portfolio, Coursework, UK

- DSM120: Financial Data Modelling, Coursework 1, UK

- DSM070: Building the Blockchain: the chain, mining, and the consensus mechanism: Blockchain Programming, Coursework 3, UOL, UK

- FHEQ Level 7 ES5800 – Systematic review protocol In this assessment you are asked to write a systematic review protocol: Analytical skills for Environmental Managers, Coursework, BUL, UK

To apply the concepts covered during the lectures to practical reactor engineering design problems: Advanced Reaction Engineering, Coursework, LSBU, UK

| University | London South Bank University (LSBU) |

| Subject | Advanced Reaction Engineering |

Part 2

Coursework Aim:

- To apply the concepts covered during the lectures to practical reactor

engineering design problems. - To develop mathematical and computational skills for the solution of reactor

engineering design problems. - To develop critical thinking about reactor design and its application in solving

current global issues.

Coursework Details:

This part of the coursework comprises two questions. The questions are about solving a series of reactor design problems where the set of equations is first specified and then solved to produce a selection of reaction profiles, such as concentration vs time, and reactor temperature vs time. Different operating regimes are considered, e.g. batch, isothermal, non-isothermal, catalytic, non-catalytic, etc. The solution of the equations may require the use of specialised engineering software, as shown during the lectures and tutorials. This part of the coursework is worth 50% of the module.

General instructions. Provide a clear development and presentation of the equations as well as the MATLAB code (or a copy of any file/software) used to

solve the equations, when applicable. The code must be presented either as

text in a Word file or as an independent .m (MATLAB) file, or any other workable file. The code must work properly when run by the marker. If the code/working file is not presented, marks will be reduced. The quality of the document will be considered in the marking.

Buy Answer of This Assessment & Raise Your Grades

Question 2

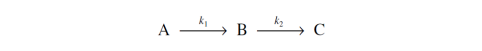

The following consecutive first-order reactions represent a hydrogenation

process:

The reaction takes place at 250 °C, and at this temperature, the reaction rate

coefficients are 𝑘𝑘1 = 0.055 min-1 and 𝑘𝑘2 = 0.008 min-1. For a liquid-phase

reaction carried out in a batch reactor where only A is charged with a

concentration of 50 mol L-1, obtain the following:

a) Present the development and the final expressions needed to determine the concentration of the different species as a function of time.

b) Present a plot showing the concentration profiles of the different species as

a function of time (up to 500 min), when no B or C are present initially.

c) The time needed to achieve 80% conversion.

d) The concentration of the different species at 500 min.

Do You Need Assignment of This Question

Question 3

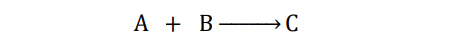

The elemental irreversible liquid-phase reaction:

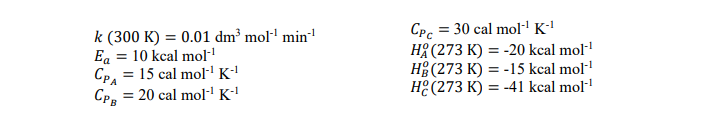

takes place in a steady-state 200 dm3 PFR, where species A and B are fed at 30 °C at a flow rate of 10 mol min-1 and 10 mol min-1, respectively. The entering volumetric flowrate is: 𝑣𝑣0 = 10 dm3 min-1. The following thermodynamic data is available:

For the case when a heat exchanger operating in co-current mode is placed

(with a UA = 1200 cal min-1 K-1) in the reactor and the working fluid temperature is constant at 70 °C:

i. Obtain the expressions to determine the concentration of the different species, and the reactor temperature, as a function of the space-time, 𝜏𝜏.

ii. Plot the concentrations of the different species as a function of 𝜏𝜏.

iii. Plot the temperature of the reactor as a function of 𝜏.

v. Determine the concentrations and the temperature at the exit of the

reactor.

v. Determine the concentrations and the temperature when the values

of the residence time is 10 min.

Learning Outcomes

This coursework will fully or partially assess the following learning outcomes for this module.

Knowledge and Understanding

- A knowledge of reactor behaviour for homogeneous and heterogeneous systems. An understanding of reaction engineering so that students can apply the principles to the solution of relevant engineering problems and to the design of reaction processes.

Intellectual Skills

- Formulate dynamic material and energy balances to give a good

representation of a chemical reactor for simple and complex reactions. - Use a mathematical approach for the design of chemical reactors.

Practical Skills

- Evaluate the performance of chemical reactors. Make provision for

heterogeneous processes. Specify temperature profiles.

Transferable Skills

- Apply principles of advanced reaction engineering to complex processes in which chemical reactions occur.

Are You Looking for Answer of This Assignment or Essay

Wondering who can help you with your coursework? Look no further! Our assignment writing help services are designed to provide students like you with the support they need to excel in their studies. Whether you’re struggling with Advanced Reaction Engineering or any other subject, our team of experts is here to assist you every step of the way. With our coursework help in UK, you can conquer even the most challenging assignments and achieve the grades you deserve.